What are welding fumes?

Welding fumes are a complex mixture of metallic oxides, silicates and fluorides. Fumes are formed when a metal is heated above its boiling point and its vapours condense into very fine, particles (solid particulates). Welding fumes generally contain particles from the electrode and the material being welded.

Welding fumes are dangerous and very threatening to health. Especially as specialists have not analysed the specific work environment and no security measures are taken.

Composition of Welding fumes

Welding fume is a varying mixture of airborne gases and fine

particles. The composition of the mixture depends on the welding

method and the products that are welded.

- Fluxes containing silica or fluoride produce amorphous silica, metallic silicates and fluoride fumes.

- Fumes from mild steel welding contain mostly iron with small amounts of additive metals (chromium, nickel, manganese, molybdenum, vanadium, titanium, cobalt, copper etc.).

- Stainless steels have larger amounts of chromium or nickel in the fume and lesser amounts of iron.

- Nickel alloys have much more nickel in the fume and very little iron.

Coating that Changes the Composition of Welding Fumes

Vapours or fumes can come from coatings and residues on metal being welded. Some ingredients in coatings can have toxic effects. These ingredients include:

- metal working fluids, oils and rust inhibitors

- zinc on galvanized steel (vaporizes to produce zinc oxide fume)

- cadmium plating

- vapours from paints and solvents

- lead oxide primer paints

- some plastic coating

Welding fumes can cause serious diseases

It is pretty obvious that it is potentially dangerous to inhale such welding fumes. And if you are not convinced, read the many scientific studies and reports stating that welding fumes can cause all kinds of physical complaints and serious diseases such as cancer, asthma and even symptoms of Parkinson’s disease.

Factors that affect worker exposure to welding fumes

- Type of welding process.

- Composition of welding rod.

- Filer metals and base metal used.

- Type of coatings present.

- Location (open area or confined space).

- Type of ventilation controls (mechanical or local).

- Work practices of welder (e.g. remove coatings, clean surfaces, stay upwind when welding in open or outdoor).

The concentration of the fume and the harmful substances are the highest in the plume of fume that rises from the welding point. The faster this fume is eliminated by ventilation, the better.

The toxicity of the fume varies. As said, it depends on the type of welding process, the welding materials used and what kind of material is being welded. In future blogs we will write more about fumes from, for instance, mild steel welding, stainless steel welding or welding of metals that are coated, and about the fume development in specific welding products and processes. How long a welder may be inhaling such a fume depends on the time he is actually welding. Some fabricators weld one or two hours a day, others weld all day long. A simple calculus, also called the arcing time, shows the longer one welds, the more fume is being produced and the greater the danger of inhaling the mixture of airborne gases and fine particles.

Composition Of Electrode/ Welding Rod

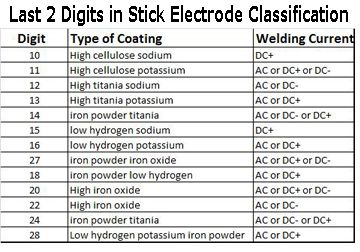

A welding electrode is made up of two parts: the actual metal, and the flux coating. The metal can vary from mild-steel, cast iron, stainless steel, high-tensile steel, copper, bronze, brass, or aluminum. The metal is then wrapped in a flux coating that is blends of cellulose, which is used by plants to give them flexibility, iron powder, and hydrogen. It is also blended with some Sodium, Titania and Potassium. The flux coating makes the electrical currents flow more evenly during the weld.

The two main ingredients of a welding rod would be iron (Fe) and cellulose (C6H10O5), which is a carbohydrate. Iron is strong, hard, magnetic, silvery-grey metal, the chemical element of atomic number 26, a transition element widely distributed as ores. Cellulose is an insoluble substance that is the main constituent of plant cell walls and of vegetable fibers such as cotton. It is a polysaccharides.

Filler Metals and Base Metals

There are many types of materials used to produce welds. These welding materials are generally categorized under the term filler metals, defined as “the metal to be added in making a welded, brazed, or soldered joint.”

The filler metals are used or consumed and become a part of the finished weld. The definition has been expanded and now includes electrodes normally considered non-consumable such as tungsten and carbon electrodes, fluxes for brazing, submerged arc welding, electroslag welding, etc. The term filler metal does not include electrodes used for resistance welding, nor does it include the studs involved in stud welding.

Long-term exposure to welding fumes may pose the risk of serious respiratory, nervous system, and reproductive effects, but more research is needed. Some metals we know are especially hazardous. These metals include lead, cadmium, beryllium, and mercury. But even welders who don’t work with these toxic materials may be at risk.

Carbon steel, which includes mild steel, is the most common material welded. The manganese in the steel and the filler metal sometimes results in overexposure to manganese. Chronic manganese poisoning can cause Parkinson’s-like disease and other neurological effects.

Stainless steel, high alloy steels, and nickel alloys expose workers to chromium and/or nickel fumes. Both nickel and hexavalent chromium are classified as human carcinogens.

Types of Coating Present

There are many types of materials used to produce welds. These welding materials are generally categorized under the term filler metals, defined as “the metal to be added in making a welded, brazed, or soldered joint.”

The filler metals are used or consumed and become a part of the finished weld. The definition has been expanded and now includes electrodes normally considered non-consumable such as tungsten and carbon electrodes, fluxes for brazing, submerged arc welding, electroslag welding, etc. The term filler metal does not include electrodes used for resistance welding, nor does it include the studs involved in stud welding.

Hazardous gases can also be produced during welding. Depending on the specifics of your process, these could include ozone, nitrogen dioxide, carbon monoxide, and fluorine compounds. These gases may cause both short and long-term effects.

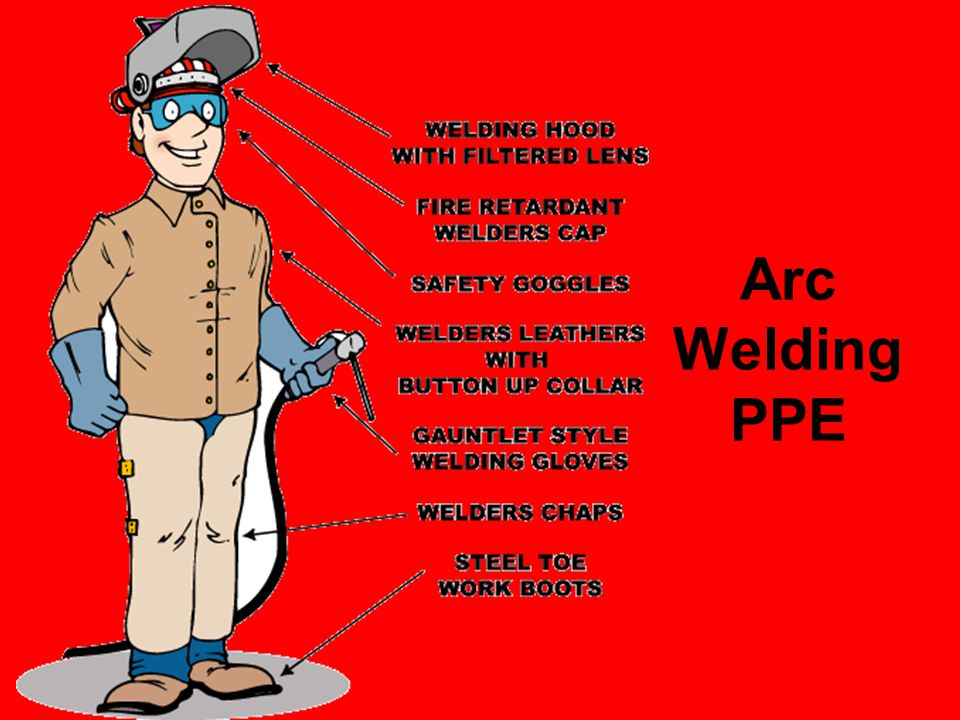

Work Practices of Welders

To protect workers from welding fumes and gases, ventilation is often necessary, especially when welding with particularly hazardous materials or for long periods. It’s essential in enclosed or confined spaces. While air-purifying respirators can filter out metal fumes, they don’t protect workers from all of the hazardous gases produced or oxygen deficiency.

Protecting Welders from Welding Fumes and Gases

Following are other simple ways to protect yourself.

- Position the Source-capture Nozzle Correctly. When using source-capture arms to remove pollutants from the breathing zone, position the arm’s intake nozzle to take maximum advantage of air velocity . A good rule of thumb is to position the arm nozzle within 4 to 8 inches of the weld, or within the same distance as the source-capture arm’s diameter, depending on the capacity of your equipment. The nozzle should be close enough to capture the pollutants but not so close that it exhausts shielding gases. The nozzle should be on the side of the weld that’s opposite you, drawing pollutants away from the breathing zone, not into your face.

- Contain Robotic Welding Space. Robotic welding, because of the quantity and speed of welds, generates a significant amount of smoke. To handle that level of fumes, use welding screens to limit the volume of air that must be captured. This step could mean the difference between concentrated cleaning of the 1,000 cubic feet of dirty air and trying to clean 800,000 cubic feet of less problematic plant air.In addition to the welding screens, place an exhaust hood directly above and close to the welding station.

- Limit Fan Use. A source-capture nozzle placed too far from the workpiece (right) causes welding fumes to remain in the breathing zone. Welders sometimes make the mistake of using fans to blow welding smoke away from the workspace—effectively making the smoke everyone’s problem. In clean-air booths, some welders aim a fan into the booth in an effort to augment the cleaning. Actually, this decreases efficiency and disrupts airflow within the booth, exposing you to pollutants that would otherwise be drawn directly into the booth’s filter area. The fan also might blow smoke out of the booth, adding pollutants to ambient plant air. Some clean-air booths are equipped with an air regain system, which washes the breathing zone with a controlled, even sheet of clean air, without diffusing smoke within the booth.

- Use Backshields and Sideshields. Downdraft table backshields and sideshields force air to be drawn down from the top and front of the table, where you generally are positioned. They help contain welding and grinding sparks in the area of the work surface, saving setup and cleaning time.Shields also allow more than one worker to use a table without distraction and protect others from inadvertent welding light hazards.

- Ventilate the Tight Spots.

- Welding under heavy equipment, in tight corners, or in difficult-to-reach places makes it easy to avoid the safety equipment that is needed most in these areas.

Perform Regular Maintenance

If safety equipment isn’t working properly, you might as well have none at all. Dirty, plugged cartridge filters impair air cleaning. Blocked hoses decrease efficiency and increase wear on fans and motors. Lowered air pressure prohibits the filter cleaning system from working properly.A quick, daily check of the cartridge filters, hoses, and system operation solves most problems before they occur. Replace worn or blown-out filters quickly, and clear or replace clogged hoses. To save costs on filter replacements, make sure your equipment has an efficient cartridge cleaning system. A Magnehelic® gauge provides a quick, simple way to check air cleaner system efficiency. The gauge measures pressure difference across cartridge filters; the bigger the difference, the more clogged the filters. For accurate readings, use a wax pen to mark the gauge’s optimum reading, and compare the needle reading to the wax mark at various times during the workday.